Professional extruder

manufacturing enterprise

Committed to the development and

production of various extruders

QA & Customer first

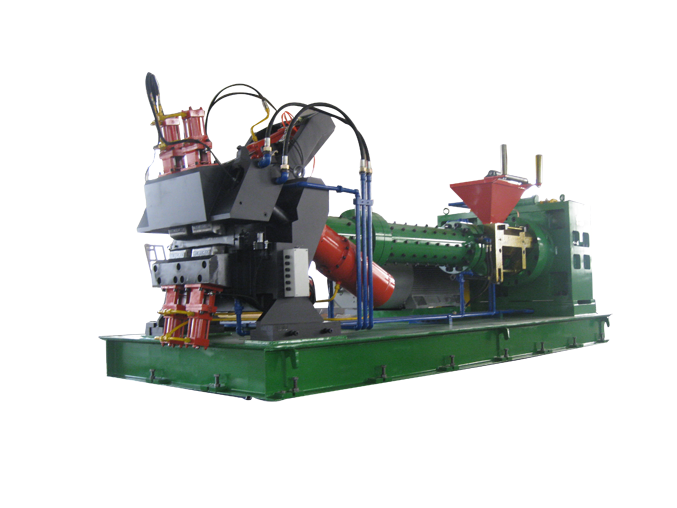

Duplex rubber extruder sets

Used:For extrusion production of different tire tread and semi-finished composite component.

Structural features:

1. The machine adopts compound technology to make the tire tread precise size and compact structure.

2. The series machines adopt introduced technologies and equipments and select the domestic ancillaries and some imported ancillaries.

3. The set is supplied in two types, dual cooling and one-cooling-one heating. It‘s also equipped with a reducer with hard-tooth gears, an automatically hydraulic tread head and a temperature/pressure measuring device.

4. The temperature of each part is controlled sectionally by intelligent temperature control device.

5. The machine is driven by a DC motor or AC motor.

6. We can design and produce any kind of compound extruder sets based on customers’ requirement.

7. According to the needs of customers, our company can provide rubber feeding device for extruder to transport rubber sheets.

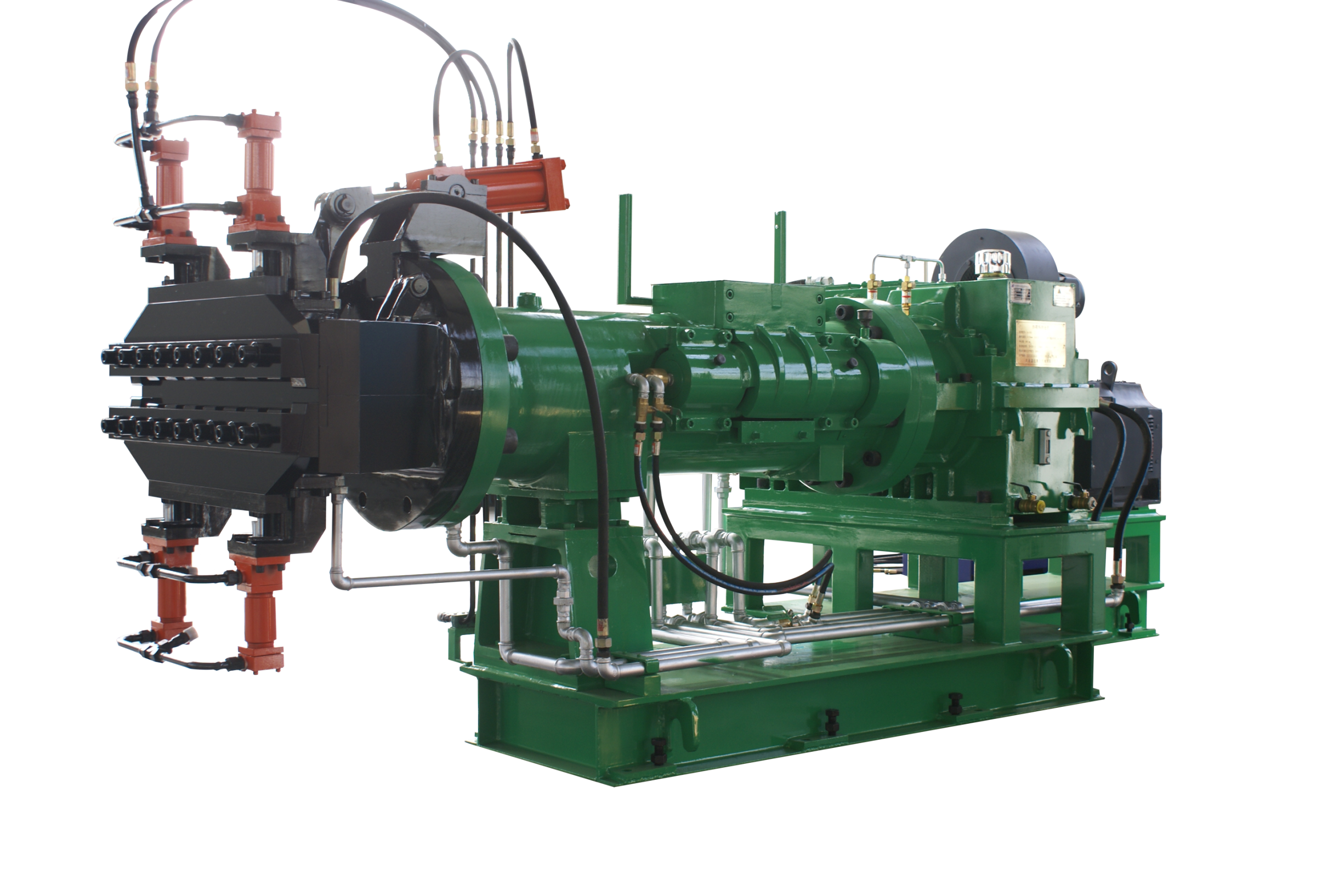

Triplex rubber extruder sets

Use:For extrusion production of different tire tread and semi-finished composite component.

Structural features:

1. The unit consists of pin barrel cold feed extruder, automatically hydraulic composite head, automatic temperature control device, and manual/automatic control system.

2. The temperature of each part is controlled sectionally by intelligent temperature control device.

3. The machine is driven by a DC motor or AC motor.

4. Introduced advanced technology, superior quality components.

5. Compact structure, neat appearance, and accurate dimension of extruded product.

6. We can design and produce any kind of compound extruder sets based on customers’ requirement.

According to the needs of customers, our company can provide rubber feeding device for extruder to transport rubber sheets.

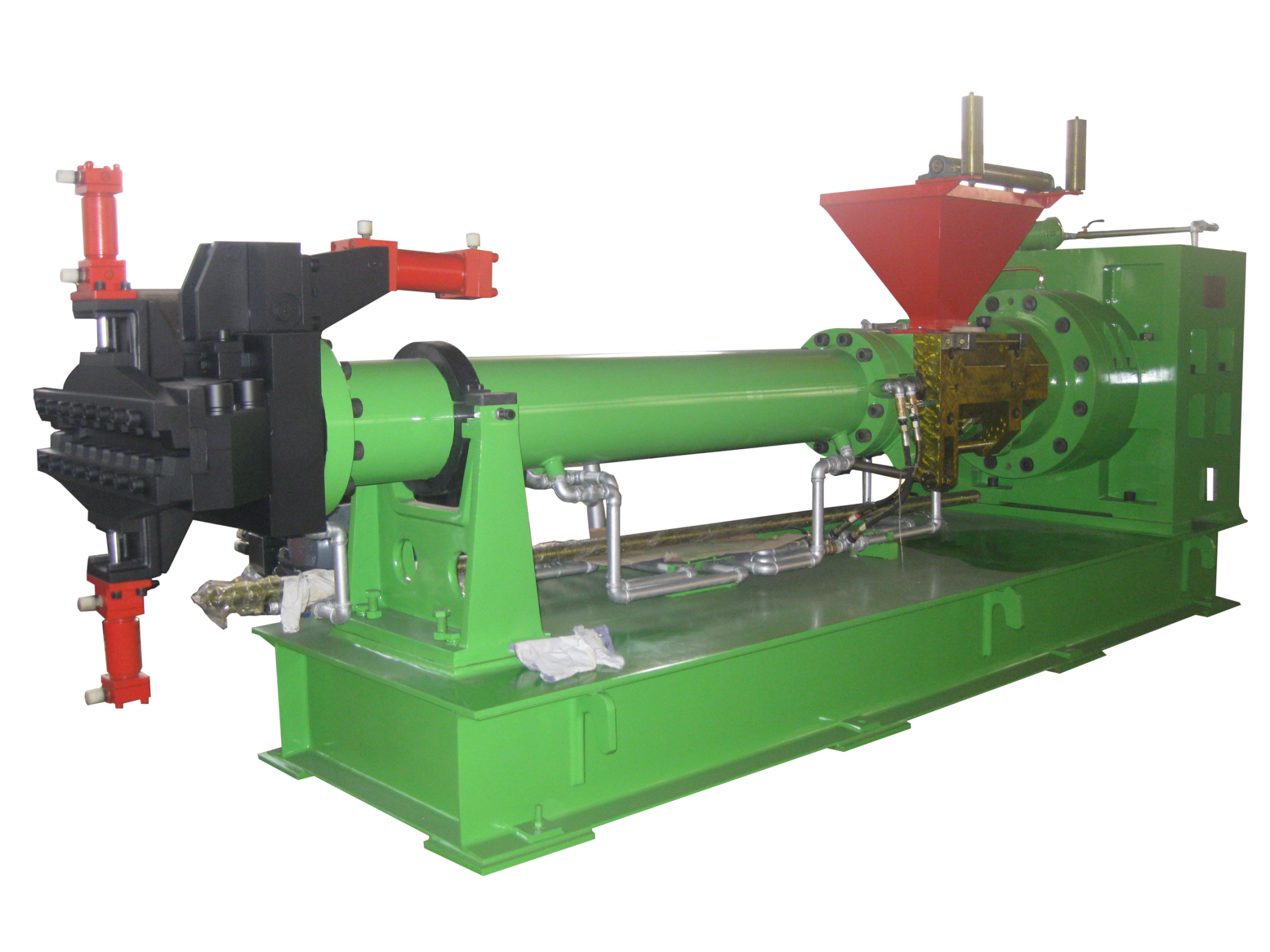

Pin-barrel cold feed rubber extruder

Use:It is used to filer the impurities from rubber stock.

Structural features:

1. The strainer equips with single/double head.

2. The head is fitted with a mechanical cutter, which operates hydraulically, the operation is simple and easy.

3. The screw is processed and polished with the foreign-made milling machine and is featured by excellent geometric precision.

4. Nitrogenation treatment makes it more wear-resistant.

5. Reducer is hard-toothed surface helical gear reducer,the gear is adopted high quality high strength low carbon alloy steel.

6. This machine is equipped with intelligent temperature control device.

7. The machine is driven by a DC motor or AC motor is featured as continuous and stable.

8. This machine takes advantages of good plasticizing effect, high filtering, low stock output temperature, and stable running.

Hot feed rubber extruder

Use:The machinery is used for the extrusion of half-finished rubber products such as tire tread, inner tube, rim band and rubber tube.

Structural features:

1. The machine is equipped with inner tube and tire tread extrusion heads and can also be equipped with other extrusion heads as required by users.

2. Temperature measuring and indicating device install in the machine body. The feeding zone over XJ-150 is equipped with side rolls for the enhancement of feeding capability.

3. The screws and bushes are subjected to nitrogenation treatment to get enough strength and wear-resistance.

4. The reducer has a forced lubrication unit, which is featured by high transmission efficiency, long service life and low noise.

5. The machine over XJ-150 is driven by speed-regulating motor. The feeding roller is driven by a variable-open type for easy rubber removal.

Cold feed rubber extruder

Use: It is used to extrude rubber semi-finish products like tire tread, inner tube, wires &cables, rubber strip, capsule, etc.

Structural feature:

1. This machine could match many heads for inner tube, tread, wires &cables, and rubber supply, so user could mention special requirements in order as demand.

2. Machine body has spiral channel, with good heat conductive effect. And in feeding section feeding roll is equipped to reinforce the feed capability.

3. Screw and bushing are all adopted nitrided steel and with nitriding treatment, so it has enough strength and good wear resistance. Screw structure is of the double threads main/subsidiary screw, with excellent plasticizing and self-cleaning.

4. Speed reducer adopts arc gear driving and equipped with reinforced lubrication system, with high drive efficiency and less noise.

5. The temperature of each part is controlled sectionally by intelligent temperature control device.

6. This machine is driven by DC motor and the machine is driven by a DC motor or AC motor is featured as continuous and stable.

Previous page

1

Next page

Copyright: Dalian Yida Rubber Machinery Co., Ltd 辽ICP备15001084号-2

CONTACT

Dalian Yida Rubber Machinery Co., Ltd

TEL:0411-89813268(总机) 89376888

FAX:0411-89813268-8020 89375678 89878588

E-MAIL:dalianyida@163.com

Address: Jianshe street, Zhuanghe City

(Korean Industrial Park)

Scanning concerns